SMD LED modules delivers higher flexibility and a lower cost, while COB LED modules offers superior luminance and more uniform illumination. Your decision will directly impact project budgets, visual performance, and long-term maintenance requirements.

This guide cuts through the technical jargon to provide a clear, side-by-side comparison of SMD and COB technologies. By the end, you’ll know exactly which solution is right for your application—whether you’re designing a video wall, control room display, or retail signage—and be able to communicate your needs confidently with suppliers.

catalogue

1.What is a COB LED Module?

COB in the LED display world means chip-on-board: thousands of bare LED dies are mounted directly onto a printed circuit board and sealed under a thin protective resin to create a seamless COB LED modules. Instead of soldering separate SMD lamp packages, this approach forms pixels directly on the board, shortening electrical paths and improving thermal stability. The result is a dense, rugged surface ideal for ultra-fine pixel pitches required in close-viewing applications.

When you see a COB LED display in person, the first thing you’ll notice is its smooth, seamless surface. This makes it resistant to fingerprints and scratches, and it can easily survive accidental bumps that would damage a regular LED screen.

COB LED display delivers three major benefits:

- Better Picture Quality: The dark, smooth surface creates deeper blacks, higher contrast, and reduces annoying glare and visual noise (called “moire”) on camera.

- Higher Reliability: Because it’s a single, solid unit, the image is more uniform and pixels fail much less often.

- Easier Maintenance: Technicians can quickly swap the entire module if needed. This is much faster than repairing tiny individual LEDs, which minimizes downtime during important events or broadcasts.

Where does COB LED modules make sense?

Control rooms, corporate auditoriums, broadcast sets, retail flagships, and premium home cinemas: any space where viewers stand within a few feet and expect spotless text, deep blacks, and color stability across long days. In short, COB is about durability and fine-pitch elegance, purpose-built for modern indoor video walls.

2.What is an SMD LED Module?

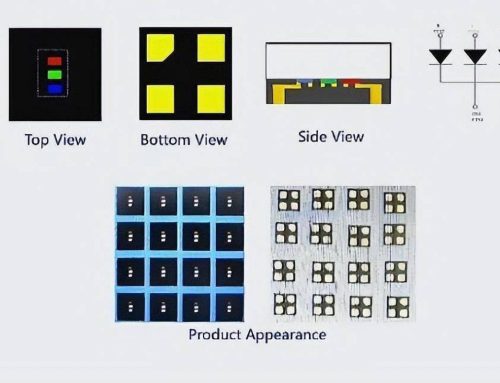

Surface-mounted devices(SMD LED modules), are built from tiny packaged LEDs that are soldered onto a circuit board. Each SMD package includes diodes of red, green and blue loaded right into a single lamp. This enables exclusive control of color and brightness.

SMD innovation has been the workhorse of the LED display industry because it is flexible, budget-friendly and scalable. You can buy SMD modules in a wide range of pixel pitches, making them suitable for everything from outdoor billboards to mid-distance indoor video walls.

For events and rentals, SMD panels are favored because they are lightweight, easy to replace and supported by a plentiful spare parts market. Technicians appreciate that problematic modules can be swapped quickly during a load-in, which keeps downtime to a minimum.

On the flip side, SMD faces challenges at very close viewing distances. The visible seams between modules and the packaging of LEDs can create texture that matters in control rooms or premium retail settings. SMD screens also tend to require careful calibration to avoid color shifts under different brightness settings.

Overall, SMD LED modules are mostly used for display projects where durability and cost matter. It remains the default option for many projects.

3.How Do You Identify a COB LED Module?

How do you tell if a wall is COB when you’re standing three feet away?

Start with the surface. A COB LED display module looks like a smooth, matte sheet under a thin protective resin; you don’t see individual “bulbs”. Run a knuckle gently across a corner (with permission): it feels solid, not like a field of tiny parts. SMD LED screen, by contrast, shows a tidy grid of little dots: red-green-blue packages, and you can spot them immediately at close range.

Next, check reflections. Shine a phone flashlight from the side: SMD LED modules’s dark coating absorbs glare and lifts perceived contrast, while COB LED modules tends to sparkle and mirror bright light. Then view some white text on deep gray. On COB, edges stay silky, even at arm’s length. On SMD, you’ll notice pixel texture sooner.

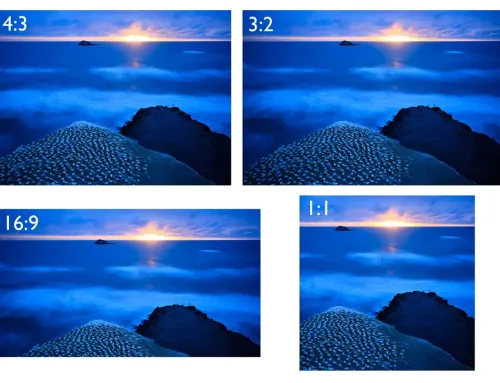

Look at seams where two modules meet. COB LED modules typically hides borders better; SMD LED modules can reveal minute misalignments. Request to check out the back label: ultra-fine pitches (0.9– 1.5 mm) are mostly COB, while mid pitches (1.9– 4.0 mm) are usually SMD.

A practical test: an AV manager comparing demo walls for a lecture hall can walk up, cue a PowerPoint slide, and instantly spot COB: quiet surface, high contrast, fewer distractions and minimal pixel noise.

4.SMD vs COB LED Module: Which one is better?

Choosing between SMD and COB modules depends on a few practical trade-offs.

SMD LED modules are versatile and cost-effective, with many pixel pitches and easy field service. They are the reliable workhorse for outdoor billboards, rental stages, and mid-distance indoor walls where easy swaps and abundant spare parts matter.

COB LED modules emphasize tight pixel geometry, smooth surfaces, and improved contrast. They shine in control rooms, broadcast sets, and premium retail where viewers stand close and expect seamless visuals. Maintenance also looks different. With SMD, technicians replace small modules quickly during load-in.

With COB, modules are robust and less prone to per-pixel failure, but module replacement can be more involved. Cost-wise, SMD systems generally start lower, especially for large outdoor formats. COB can carry a higher upfront price for equivalent apparent resolution, but buyers often value lower visible seams, longer uniformity, and fewer visible defects over time.

In short, choose SMD LED modules for its flexibility, budget and serviceability. Choose COB LED modules when fine pitch elegance, durability, and camera-friendly screens are the priorities. Both technologies work well when matched to viewing distance and content goals. If unsure, request demos at target viewing distances and compare live footage before buying.

5.SMD LED Module Applications: When Should You Choose It?

Surface-mounted device modules remain the go-to choice for many LED display projects because they balance cost, flexibility and serviceability.

If you are buying LED panels for outdoor advertising, touring stages or a national signage rollout, SMD LED modules deliver a wide range of pixel pitches and straightforward module swaps that cut downtime. Rental and production teams favour SMD because the modules are lightweight and modular, allowing technicians to swap a cabinet during load-in and get the show back on track.

Retail chains often choose SMD LED modules for in-store walls and window video because the viewing distance makes seams unnoticeable, while color and brightness are excellent. For stadium perimeter advertising and highway billboards, SMD stands out thanks to high brightness and proven weatherproofing. SMD panels also make sense when spare parts and local support are priorities, since the ecosystem for SMD components is mature and widely available.

Before you buy, ask the vendor for a live demonstration at the precise viewing distance, confirm front service access and spare module compatibility, and check estimated lead times for replacement parts. In many practical scenarios, SMD offers the best blend of performance predictability and total cost of ownership. They are proven on countless installs.

6.COB LED Module Applications: Why Is It Ideal for High-End Projects?

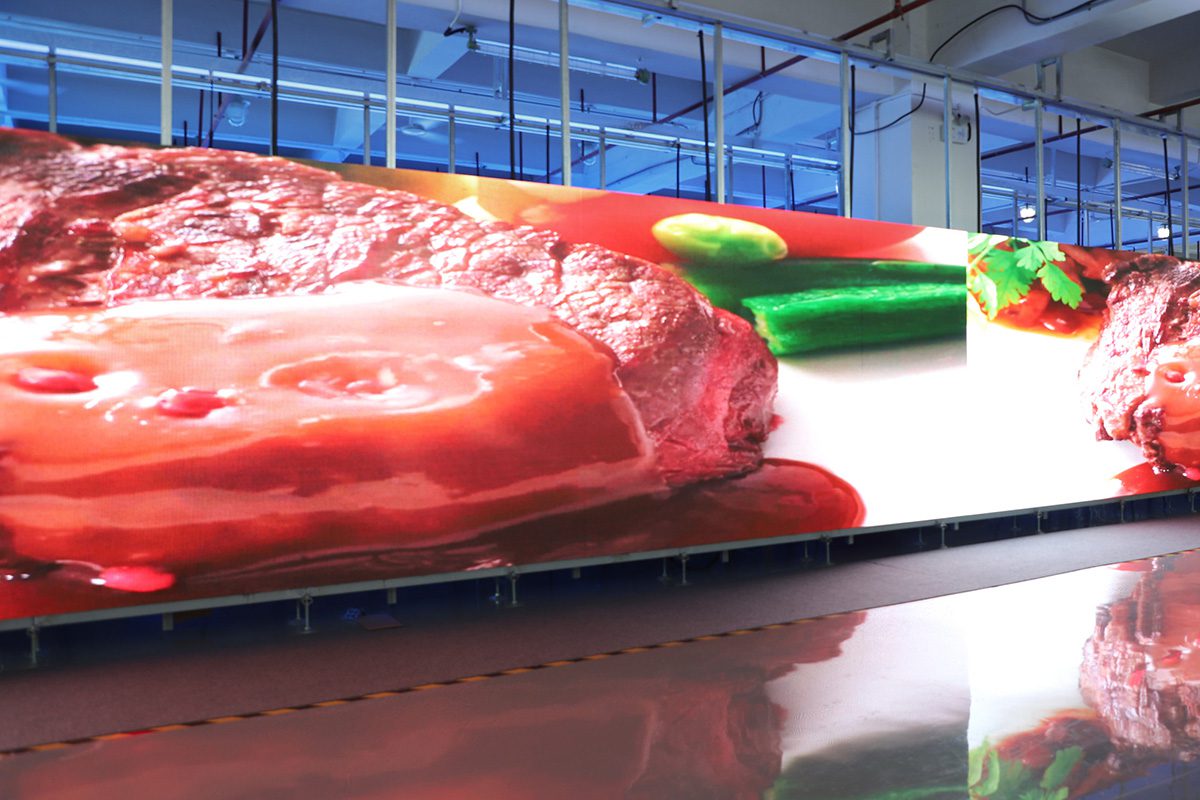

COB LED modules are ideal when the brief demands immaculate visuals, tough surfaces, and low visual noise at close range. Think control rooms, boardrooms, broadcast sets, luxury retail, museums, airports, and premium residential theaters; places where viewers stand a few feet away and notice everything. The resin-sealed surface gives a smooth, matte plane that hides pixel boundaries, so text looks razor clean and skin tones stay natural on camera. That makes COB a dependable choice for signage, data walls, and any display that must look flawless under bright lights.

In high-end retail, COB LED modules help products look luxurious: black levels are deeper, reflections are subdued, and the display can handle fingerprints or bumps from daily traffic. Museums and galleries appreciate the uniform surface for captioning, animated labels, and delicate gradients that shouldn’t shimmer. In airports and premium transit hubs, COB’s durability and clarity support wayfinding and commercial messaging where readability and uptime matter more than raw brightness.

Events and corporate auditoriums benefit from COB when the stage design brings screens close to presenters and cameras. The reduced moiré and tighter pixel geometry play nicely with 4K broadcast workflows and hybrid meetings. In places where privacy or fine detail is critical, such as trading floors, medical teaching theaters, engineering review rooms, COB LED modules help preserve thin lines and small type without the “sparkle” that can distract decision makers.

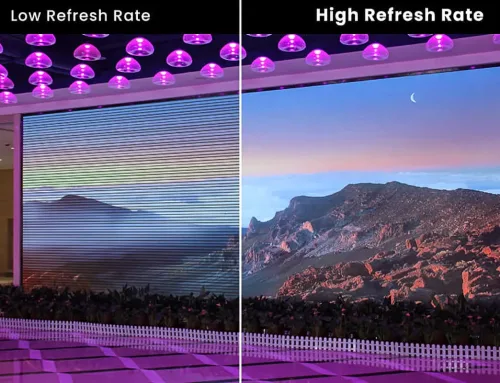

Cameras exaggerate flaws that the human eye might forgive, such as tiny brightness differences, pixel sparkle, or moiré interference. The smooth resin layer on COB acts like a diffuser, softening the “grid effect” that causes shimmer on video. The darker coating cuts glare, so studio lights don’t bounce back into the lens. With uniform pixel geometry, lines of text stay sharp and skin tones render naturally, without the wavy patterns that can spoil a feed. Operators and production crews trust that the wall will look as polished on camera as it does in the room.

COB LED module is an investment that trades a slightly higher upfront cost for enduring visual quality, durability, and professional confidence. That reliability builds trust with operators everywhere. It’s built for demanding, design-led and mission-critical spaces.

7.Maintenance & Longevity: What to Expect from SMD vs COB

When you choose a LED display, maintenance and longevity will shape how it performs over months and years, often more than the initial sticker price. SMD and COB behave very differently in the field, and understanding those patterns helps you plan budgets, spare parts, and service routines without surprises.

SMD LED modules win on modular serviceability.

If a lamp, pixel group, or small PCB fails, technicians replace the faulty module or lamp package quickly. For rental companies and stadium perimeters where panels are handled, moved and stored often, SMD LED modules’s replaceability keeps downtime minimal. SMD ecosystems also benefit from a broad spare-parts market; replacements are usually cheaper and locally available in most regions.

COB LED modules prioritises surface integrity and long-term uniformity.

Individual LEDs are bonded and encapsulated, making per-pixel failures less common. When a fault occurs, teams typically swap entire modules rather than reworking microscopic parts, which can mean slightly longer service windows but fewer overall interventions. For control rooms, museums, and broadcast studios-spaces where consistent color and fine details matter: COB’s stability reduces the need for frequent calibration and cosmetic touch-ups.

Environmental exposure matters. Outdoor SMDs with proper IP ratings withstand rain, dust, and sun, while indoor COBs benefit from stable, climate-controlled environments. Heat and poor ventilation accelerate ageing for both technologies, so thermal management is critical. Routine cleaning, dust control, and avoiding direct sunlight prolong life; simple maintenance checklists (monthly visual inspection, quarterly calibration, annual module audit) keep surprises low.

Total cost of ownership revolves around purchase price, energy use, repair parts, and downtime costs. SMD LED modules often starts cheaper and is easier to scale, but frequent small repairs and color drift can add labour costs. COB LED modules carries a higher upfront cost but reduces visible defects and camera-related troubleshooting over time.

Practical tips: secure a spare kit tailored to your tech, insist on front access if the room layout needs it, lock in an SLA for response times, and schedule regular calibration. Treat maintenance as part of the design brief: a little planning up front saves a lot of last-minute stress during live events or launches.

8.Cost Considerations: Upfront vs Long-Term Investment

Cost considerations should focus on total cost of ownership, not just the sticker price.

SMD systems typically carry a lower upfront cost, especially for large outdoor displays, highway LED billboards, and rental fleets where surface area determines budget. That entry-level affordability makes SMD attractive to advertisers, event production companies, and municipalities. SMD parts are commoditized, spare modules are widely available, and local technicians can replace units quickly, keeping short-term repair expenses manageable.

COB LED modules usually demand a higher purchase price per square metre because of denser die placement, specialized assembly, and tighter quality control. The premium buys superior uniformity, fewer visible defects, reduced seam visibility, and longevity of color integrity; attributes valued in retail flagships, broadcast studios, corporate boardrooms, and galleries. Over time, the improved consistency can lower brand risk and reduce expensive on-camera troubleshooting.

To evaluate lifetime cost, itemize energy consumption, spare parts inventory, maintenance labour, downtime exposure, calibration cadence, and anticipated refresh cycles. SMD’s modularity reduces labour per swap, but frequent small fixes accumulate labour costs. COB lowers per-pixel failure rates but may require full-module replacements and careful recalibration; such interventions occur less often but can cost more per incident.

Procurement should weigh warranty length, service level agreements, available local support, and spare-part lead times. A longer warranty and rapid SLA can justify higher capital expense. Also assess upgrade paths: choose platforms that allow future pixel-pitch improvements without full replacement.

Practical tips: insist on demos at real viewing distances, request a five-year total cost forecast, verify spare-part availability, and build maintenance into the capital plan. In short, choose SMD where scale, brightness, and cost-efficiency are of priority; choose COB LED modules where visual fidelity, camera performance, and long-term brand protection justify the cost.

Finally, record actual post-installation metrics and compare them to vendor promises to inform future procurement decisions and budget forecasts.

9.FAQs

10.Conclusion

When you’re deciding between COB LED modules and SMD LED modules, think less about which one is “better” and more about what you actually need. COB has a clear edge in durability and clean visuals. With its tightly packed diodes, you don’t see the tiny gaps between pixels. That makes a difference if you want a premium display in a shopping mall or an outdoor board where passersby expect crisp quality. Maintenance is easier too, since there are fewer points of failure. The downside? COB usually costs more and doesn’t give you as many options in pixel pitch.

SMD LED modules, meanwhile, is the workhorse of the LED world. It comes in countless configurations and is cheaper to roll out at scale. Event companies like it because rental modules can be swapped quickly, and you can hit very fine resolutions for close-up viewing. But SMD modules need more care over time, and on huge outdoor walls, they don’t always look as smooth as COB LED modules.

So, which should you choose? The real answer depends on where that screen will be utilized, how much you want to spend, and how often you’ll have to maintain it. That balance, not the “label”, determines success.